Technologies

Explore integrated SIGNRACER technologies

Chassis

Printhead Technology

Thanks to our development partnership and OEM agreement with Ricoh, Signracer is now the only company offering the Gen.5s with 2.5 pl, and one of the first companies offering Gen.6. Ricoh’s smaller drop print heads are suitable for special applications that require higher precision, such as watch faces and industrial components.

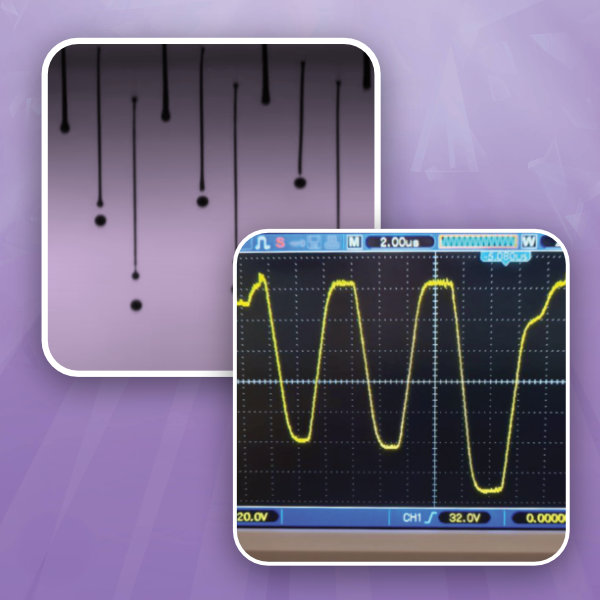

Waveforms

We develop our own inks and wave forms, which is extremely important for small drop print heads like Gen. 5s and high frequency like Gen. 6. This feature allows us even higher print output, and top quality at maximum printing speeds without compromise. Signracer waveforms are a perfect match with our ink formulations especially in grayscale printing.

LED UV System

We use the UV integration LED System, which has very high performance and air cooling (no water cooling tubes in cable chain!). These LEDs Systems are offered with 3 years warranty. Modular design allows custom LED UV configurations for applications with varnish and primer. LED UV lamp features long life and light wavelength that perfectly matches the ink and varnish with optional delayed curing for primers.

LED UV Adjustments

Our LED is adjustable from 10-100% with maximum power of 16 Watt/ cm2. High settings allow quick curing and the best adhesion and lower LED performance can be benefitial for further production processes (CNC machining, stretching materials, etc.)

Ink Bottles

The ink bottles are also used as the printer ink reservoirs. We achieve slow aging of the ink because old inks are never mixed with new inks. This results in a very stable printer and no sediments in the bottles because they are always changed.

OEM Inks

Signracer OEM inks are produced by Nutec Digital according to highest quality standards. Our low viscosity ink formulation is running at only 38°C – 40°C, which requires less cleaning during operation and reduced ink aging in the system. We offer industrial print solutions to print on leather (long-term high flexibility) and highest adhesion on all kind of materials.

Greenguard Certified

The GREENGUARD Gold Certification ensures the interior products are low in chemical emissions, decreasing indoor pollution levels. This program sets the most stringent guidelines for total VOC emissions. Greenguard Gold Certified products emit minimal gases. They maintain healthy indoor air quality, by reducing our chemical exposure. Low level of formaldehyde emissions specifically, makes them suitable for use in child’s room or educational settings which has to meet even stricter standards. Lower emissions mean healthier indoor air, thereby reducing the risk of asthma, allergies, respiratory diseases; eye, nose, throat irritation; reproductive and developmental defects; various diseases and forms of cancer.

Digital Primer

Signracer integrated digital primers can print these adhesion promoters under printed areas only. Our high-performance UV LED technology is curing the primers directly or with delayed curing. Delayed curing forms solid film-like surfaces, suitable for all industrial production purposes with challenging materials. The solid primer film provides the strong adhesion to the material and creates unique effects using white and colour on the top.

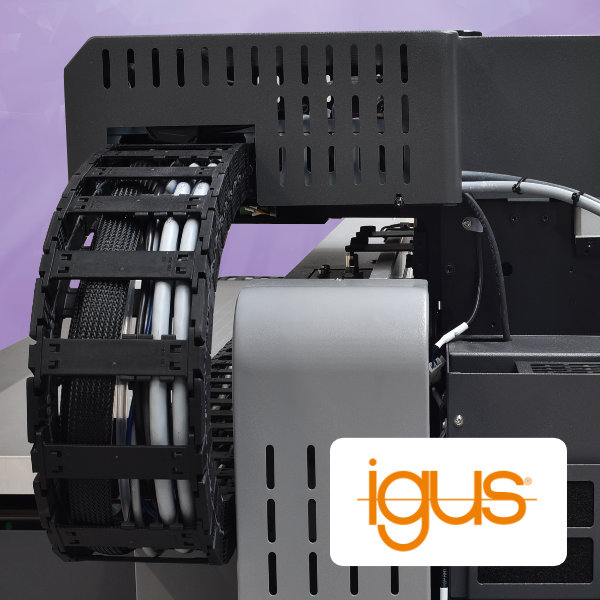

Cable Chain

Cable chain from IGUS in Germany for 24/7 operation. Cable chains are referred to as the lifeline of modern machinery. These durable cable carriers ensure a safe supply of energy, data and inks while under constant motion. Tested for over 2 Million cycles!

Anti-Static

Our Anti-static is located between the print heads and LED for highest efficiency. Maintenance friendly design allows easy cleaning of antistatic module. Antistatic carriage module from Kersten in Germany is chosen for it’s highest performance. KERSTEN has been the leading supplier of system solutions for electrostatics for over 40 years.

CE Certification

European CE certification makes sure that all components of our printers are in accordance with European standards. In addition we offer technical support through our experienced engineering team for all our customers across Europe.

The Signracer printers meet Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006. This machinery directive defines the safety components to avoid accidents. EN ISO 12100 – Safety of machinery – General principles for design – Risk assessment and risk reduction. EN 60204-1:2006 + A1:2009 + AC:2010 Safety of machinery – Electrical equipment of machines – Part1: General requirements. EN 1010-1:2004+A1:2010 Safety requirements for the design and construction of printing and paper converting machines. Industrial printers meet the category 3 of SN EN ISO 13850 – Safety of machinery – Emergency stop function – Principles for design with Category 3 requires redundant relays and switches. In addition, we are able to integrate light curtains for further safety and protection.